We help reduce total costs by optimizing indirect material procurement.

Service overview

Potential issues in indirect material

procurement at manufacturing factories

From application to approval of indirect material purchases, to managing large quantities of inventory, replenishing shelves when materials are out of stock on weekends, holidays, or at night, and taking inventory before the closing date

- Are you having trouble with a mountain of work piling up outside of your actual manufacturing operations?

Requesting applications and approvals from multiple people

Complicated approval process

Oversights due to manual inventory management

Stock shortages, and emergency orders

Excessive inventory of indirect materials

due to site-specific management and ordering

Time-consuming usage management

Unclear usage

Calculate payment amount based on monthly usage amount

No need to stocktaking work

Improving the efficiency of production in factories is an unavoidable issue for our customers,

but they have no concrete ideas to reduce indirect material costs.

will solve your problem.

will solve your problem.

The value of time provided by MISUMI floow

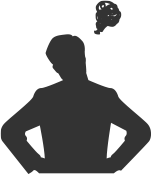

Build a total supply chain for indirect materials according to customer purchasing frequency

The value of time provided by MISUMI floow

Inventory-less

No inventory costs incurred from vending machines

Items in vending machines remain Misumi inventory assets and are only billed when the items are removed.

Order-less

Automatic replenishment/

Regular delivery

Data alignment allows Misumi to automatically manage and replenish inventory

Management-less

Visualize your inventory data

Daily usage data is provided and can be checked on the dashboard

Fraud Prevention

Strengthening governance

Make management transparent by visualizing who used what, when, and how much

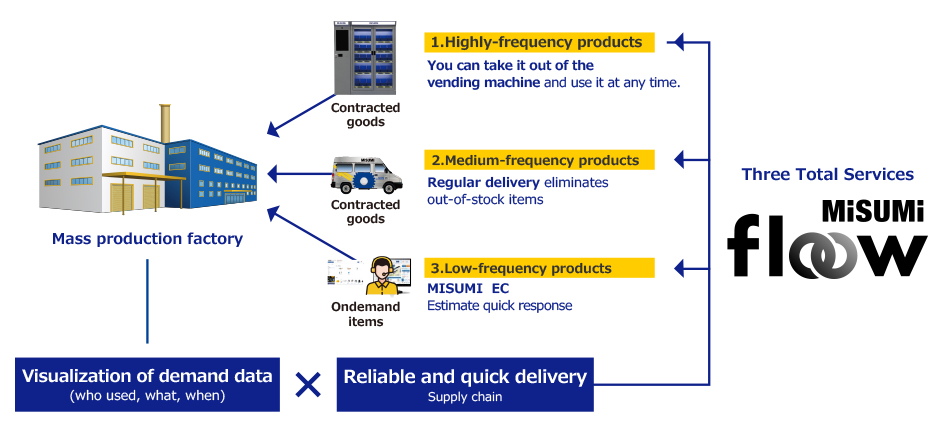

Reduced procurement operations at the five companies

that introduced MISUMI floow !

※The total number of hours saved is the total for the year.

※Calculated from the average time per line at five participating companies.

Features installed in MISUMI floow vending machines

Available 24 hours a day,

365 days a year

Identify users

Log in with ID card or face recognition

Automatically order inventory

Provides usage data

Inquiry

If you are interested in implementing this system or have any questions, please contact us here.

Our staff will contact you shortly.